Tumble Steel Belt Shot Blasting Machine for Middle & Small Castings

Key Specifications / Features

Model No.: JX-TBM-03

Hits: 494

Shot Blasting Machine Supplier JX Offers Tumble Steel Belt Shot Blasting Machine for Small Castings and Middle Castings, Suitable for Clean-up Lines.

Request a quote

Tags

Previous: Rubber & Steel Belt Tumblast Machine

Detail Information

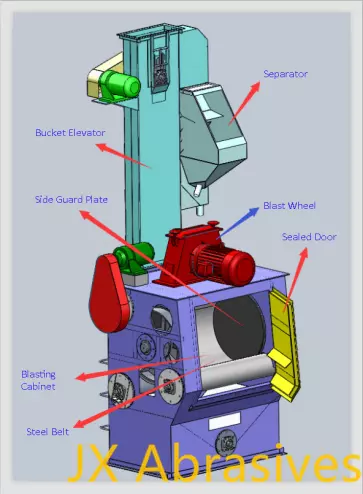

Tumble Steel Belt Shot Blasting Machine

Application:

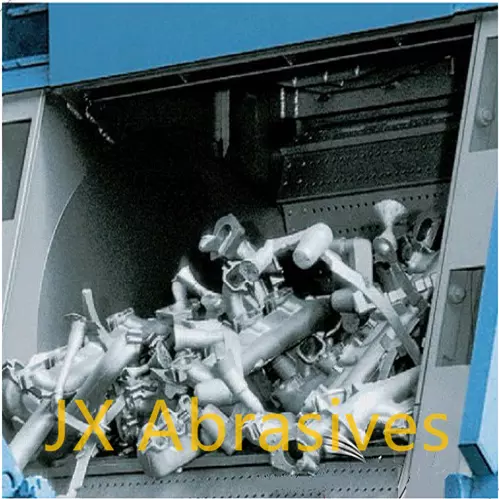

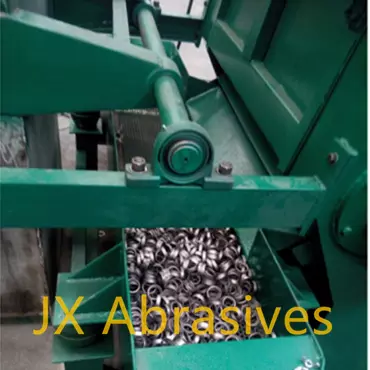

1.Used for surface cleaning, rust removing and surface intensification of various middle and small size castings, forging products and workpieces.

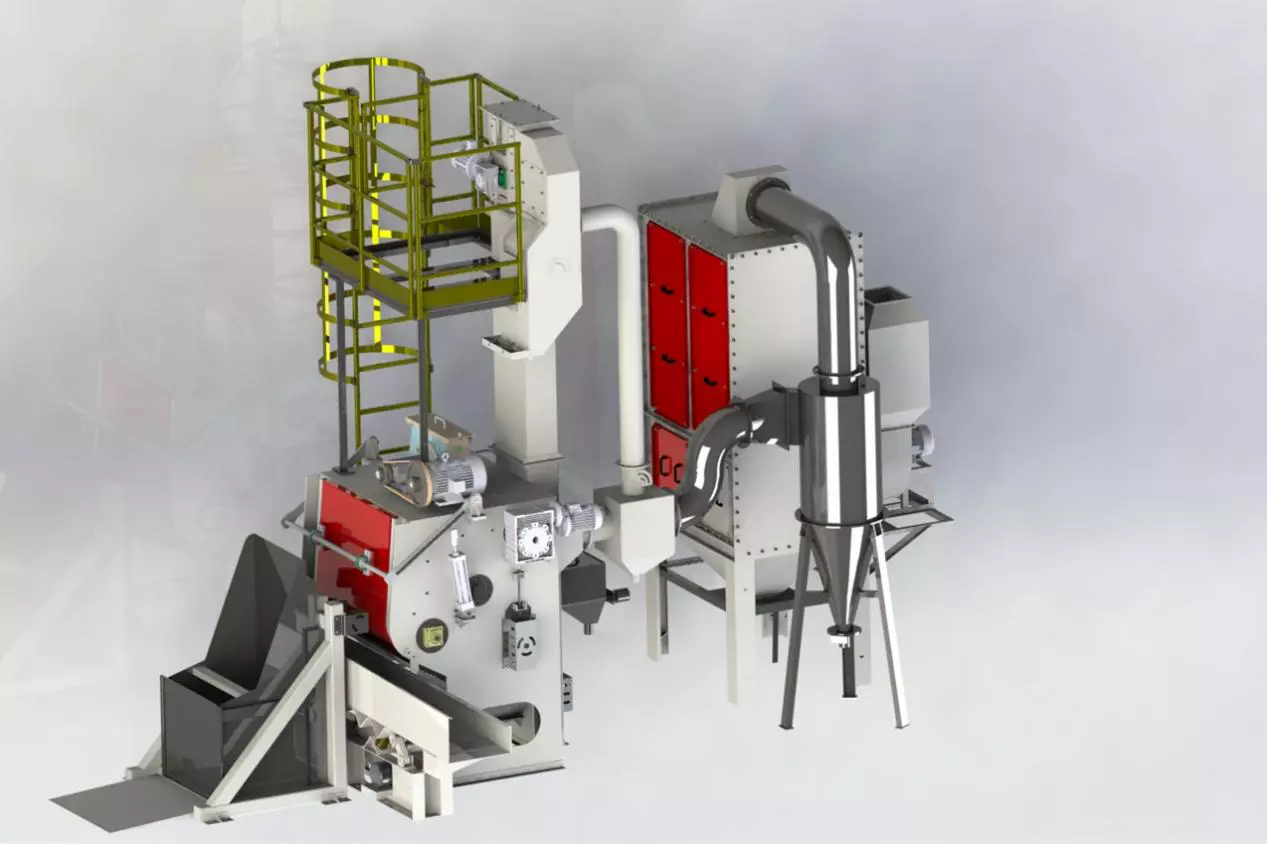

2. Suitable for different production scale and can also be used in conjunction with the continuous conveyor components to form the production of clean-up lines.

3. Advanced design, reasonable structure

4. Little energy consumption and high efficiency.

1.Used for surface cleaning, rust removing and surface intensification of various middle and small size castings, forging products and workpieces.

2. Suitable for different production scale and can also be used in conjunction with the continuous conveyor components to form the production of clean-up lines.

3. Advanced design, reasonable structure

4. Little energy consumption and high efficiency.

Main Technical Parameter:

Main Machine

Outline Dimension(L*W*H): 4300mm x 3500mm x 6200mm

Workpiece

Maximum Dimension: **mm

Maximum Weight: 20 kg/pc

Blast Cleaning Effect (GB8923-88): Sa2.5

Surface Finishing Roughness: 10~50 mu

Cleaning Efficiency Requirements: > 1500 kg/load

Main Machine

Outline Dimension(L*W*H): 4300mm x 3500mm x 6200mm

Workpiece

Maximum Dimension: **mm

Maximum Weight: 20 kg/pc

Blast Cleaning Effect (GB8923-88): Sa2.5

Surface Finishing Roughness: 10~50 mu

Cleaning Efficiency Requirements: > 1500 kg/load

If you're interested in our style machine, welcome to contact us to get more detailed info.

This machine is not a standard machine, any parameters can be customized according to clients' requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions

Production Lead Time:

1. Within 7 days after contract signed and downpayment received, JX ABRASIVES will provide customer with equipment system diagram and layout designing chart, foundation pit desian drawing, embedded part drawing, electric power, technical documents for confirmation.

2. Manufacturing Time: 20 Working Days

3. China Inland Transportation & Customs Clearance Time: About 7 Days

4. Customer Site Installation and Comissioning Time: About 8 Days

Quality Assurance & After-sales Service:

One Year (Consumable Parts Excluded)

24 Hours After-sales Service Line: +86 592 5185561

Note: Detailed Quality Assurance Plan and Service contents will be defined in Sales Contract afterwards.

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer's shot-blasting needs. If you have special requirements, please download Blasting Equipment Questionnaire for your reference.

Comment Form