Steel Bar Shot Blasting Machine

Key Specifications / Features

Model No.: JX- RCBM-02

Hits: 457

Steel bar shot blasting machine from JX manufacturer are more uniform cleaning, brighter finish and they may be cold drawn, turned, and polished.

Request a quote

Tags

Detail Information

JX Abrasives manufactures customized steel bar shot blasting machine to meet the customers’exact specifications, our machine is superior to any other typical equipment manufactured by other companys. Our machine from single wire to multi bar machine, processing up to 18 bars at a time.

This machine is not a standard machine, any parameters can be customized according clients’ requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions.

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer’s shot-blasting needs. If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Steel Bar Shot Blasting Machine is widely used for metal gridding, steel tube, petroleum, chemical, electric power industry. It is a kind of dry cleaning machinery. In the process of forming, processing, transporting and storing of the work piece, there will always be oxide coating, rust, slag, dust, oil and others on the surface. The Steel Bar Shot Blasting Machine uses high-speed blast to strike and cut the surface of the work piece in dry and non-fluid media, and realize the cleaning purpose.

Typical Application:

1. Remove rust and oxide layer on the surface of the wire.

2. After blasting, wire rod surface presents a uniform roughness, which will help to increase the adhesion of the aluminum clad copper clad, cladding uniform will never fall off.

4. Eliminate the internal stress generated in the wire drawing process.

5. Increase the wire surface tensile strength and resistance to stress corrosion cracking, permanent life. The machine is best suitable models for wire surface oxide skin treatment.

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door

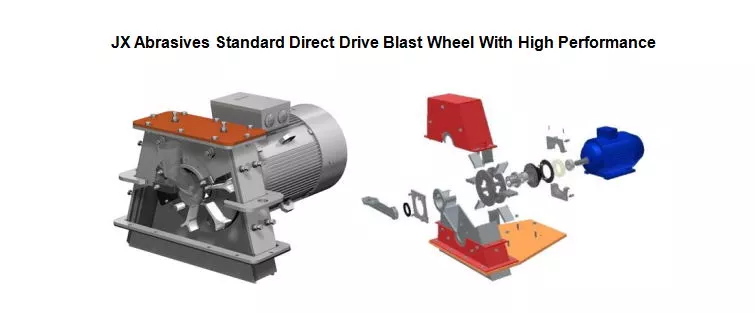

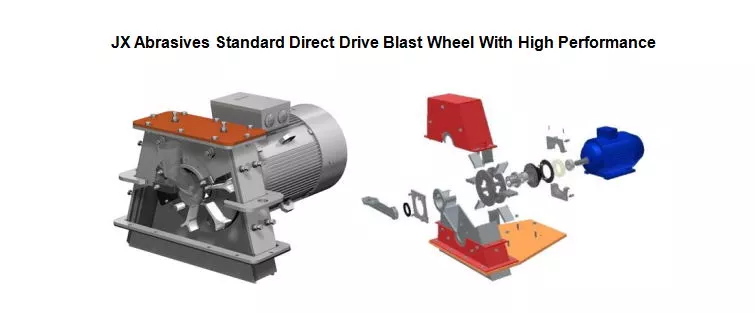

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit

4. Bucket Elevator unit

5. Abrasive Separation/Cleaning system with Storage Hopper

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with PLC Control System.

Technology Parameter(Customized is available):

Typical Application:

1. Remove rust and oxide layer on the surface of the wire.

2. After blasting, wire rod surface presents a uniform roughness, which will help to increase the adhesion of the aluminum clad copper clad, cladding uniform will never fall off.

4. Eliminate the internal stress generated in the wire drawing process.

5. Increase the wire surface tensile strength and resistance to stress corrosion cracking, permanent life. The machine is best suitable models for wire surface oxide skin treatment.

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit

4. Bucket Elevator unit

5. Abrasive Separation/Cleaning system with Storage Hopper

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with PLC Control System.

Technology Parameter(Customized is available):

| Steel Bar Shot Blasting Machine | ||||||

| Model | DX10 | DX15 | DX20 | DX25 | DX30 | DX140 |

| Work piece size(mm) | 30*100 | 50*150 | 50*200 | 50*250 | 50*300 | 150*1400 |

| Shot capacity(kg) | 2*250 | 2*250 | 2*250 | 2*250 | 2*1000 | 2*1000 |

| Elevating capacity(kg) | 30000 | 30000 | 30000 | 30000 | 30000 | 1200000 |

| Separating capacity(kg) | 30000 | 30000 | 30000 | 30000 | 30000 | 1200000 |

| Air volume(m³/h) | 5000 | 5000 | 5000 | 6000 | 6000 | 10000 |

| Power(kw) | 50 | 50 | 50 | 50 | 50 | 115 |

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer’s shot-blasting needs. If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Comment Form

-400x400.webp)