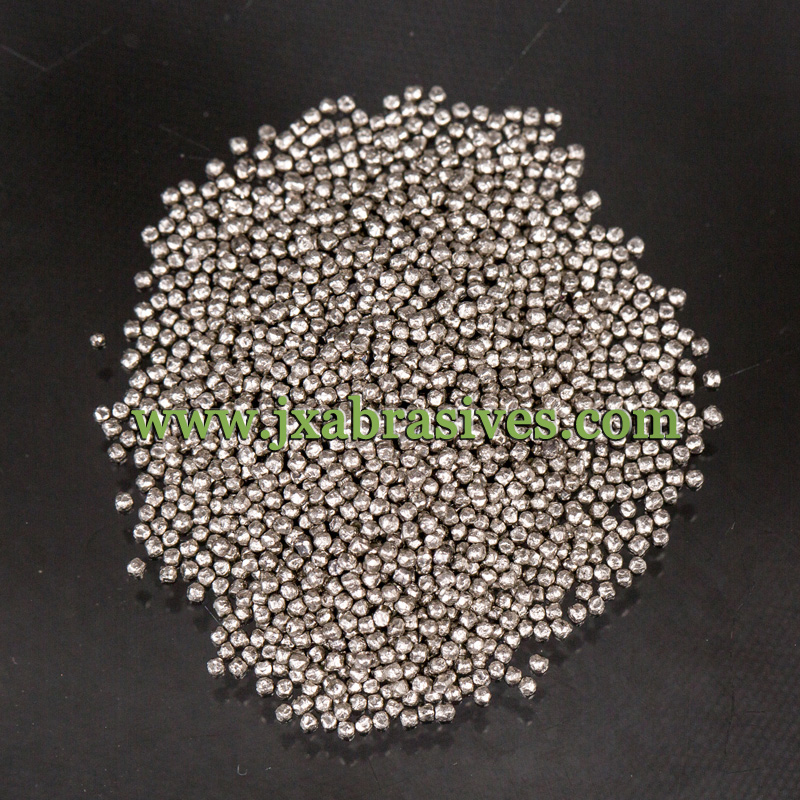

Stainless Steel Shot

Key Specifications / Features

Model No.: JX 15 SS 01

Hits: 1753

Buy Stainless Steel Shot from Jinxing Abrasives Manufacturer in China, Stainless Steel Shot 0.2-3.0 mm, 7.7g/cm3, SUS 304, SUS 202, SUS 430 grades.

Request a quote

PDF

Tags

Next: Copper Shot

Previous: Zinc Shot

Detail Information

Quick Details:

Size: 0.2mm-3.0mm.

Hardness: 200-450/400-600/600-700HV.

Density: 7.7g/cm3 Min.

Available Grades: SUS 304, SUS 202, SUS 430.

Description:

Stainless steel shot is used for cleaning, deburring, descaling and surface finishing of a wide variety of stainless steel, titanium, aluminum, or other non-ferrous alloy castings, molds and fabrications. The 316 type stainless steel has good resistance to chloride corrosion, it is suitable used in the marine environment. Due to non-magnetic, it is also used in tumbling or vibratory applications.

Size: 0.2mm-3.0mm.

Hardness: 200-450/400-600/600-700HV.

Density: 7.7g/cm3 Min.

Available Grades: SUS 304, SUS 202, SUS 430.

Description:

Stainless steel shot is used for cleaning, deburring, descaling and surface finishing of a wide variety of stainless steel, titanium, aluminum, or other non-ferrous alloy castings, molds and fabrications. The 316 type stainless steel has good resistance to chloride corrosion, it is suitable used in the marine environment. Due to non-magnetic, it is also used in tumbling or vibratory applications.

| Standard of Country | Chemical Composition | Micro- Structure |

||||||||||||

| USA | German | UK | Japan | C Max | SI Max | Mn Max |

P Max | S Max | Ni | Cr | Mo | N Max |

||

| AISI | W-Nr | DIN KURZNAME | BS | JIS | ||||||||||

| 201 | 1.4372 | SUS 201 | 0.15 | 1 | 5.5-7.5 | 0.06 | 0.03 | 3.50-5.50 | 16.00-18.00 | 0.25 |

Austenitic |

|||

| 202 | 1.4373 | SUS 202 |

0.15 | 1 | 7.5-10.0 | 0.06 | 0.03 | 4.00-6.00 | 17.00-19.00 | 0.25 |

||||

| 301 | 1.4310 | X12Cr Ni 177 | 301S21 | SUS 301 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6.00-8.00 | 16.00-18.00 | - | ||

| 304 | 1.4301 | XDCr Ni 189 | 304S16 | SUS 304 |

0.08 | 1 | 2 | 0.045 | 0.03 | 8.00-10.50 | 18.00-20.00 | - | ||

| 316 | 1.4401 | X15 Cr Ni Mo 1810 | 306S16 | SUS 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 | 2.0-3.0 | ||

| 410 | 1.4006 | X10 Cr 13 | 410S21 | SUS 410 | 0.15 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.50-13.50 | - | Martensitic |

|

| 430 | 1.4016 | X8Cr 17 | 430S17 | SUS 430 | 0.12 | 0.75 | 1 | 0.04 | 0.03 | 0.6 | 16.00-18.00 | - | Ferritic |

|

Comment Form