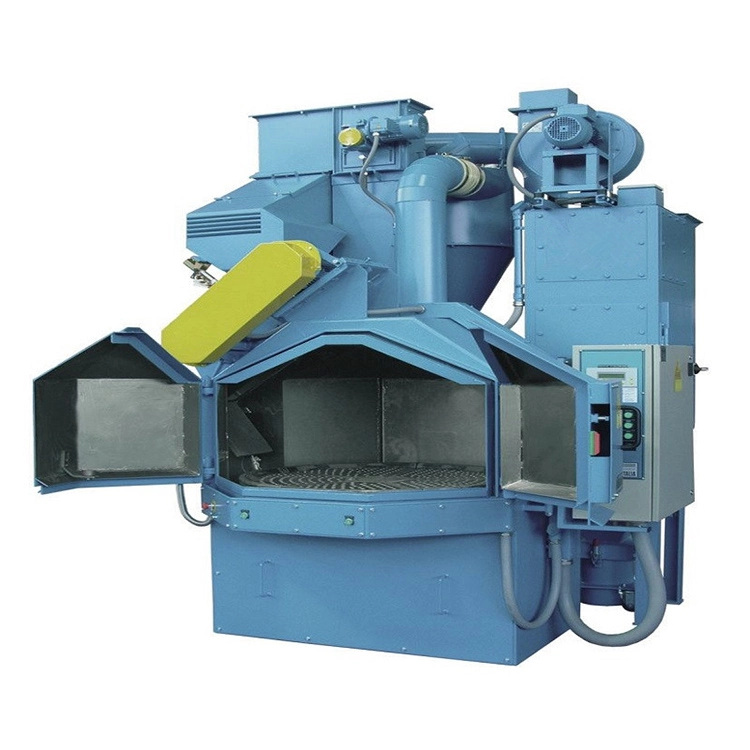

What IS Rotary Type Shot Blasting Machine?

Rotary shot blasting machine is mainly suitable for mass production of surface cleaning of small and medium-sized workpieces. This specification equipment is suitable for engine connecting rods, gears, diaphragm springs, etc., widely used in casting and automobile manufacturing, with high production efficiency and sealing effect Good, compact structure, convenient loading and unloading parts, high technical content and other characteristics.

Rotary shot blasting machine is mainly suitable for mass production of surface cleaning of small and medium-sized workpieces. This specification equipment is suitable for engine connecting rods, gears, diaphragm springs, etc., widely used in casting and automobile manufacturing, with high production efficiency and sealing effect Good, compact structure, convenient loading and unloading parts, high technical content and other characteristics.The planetary rotary shot blasting machine adopts the "mother-mother rotation" operation mode (usually 2-24 small turntables), which is suitable for the shot blasting of various small processing parts after heat treatment to remove the oxide scale, so that the surface of the workpiece reaches silver gray and has It can remove the stress and improve the adhesion of the surface coating; the shot blasting process can also be used to increase the surface prestress of the above-mentioned workpiece, improve the fatigue strength, and achieve the purpose of shot blasting. The design concept of the planetary rotary shot blasting machine is to load and unload new parts while other parts are being processed, forming a complete manufacturing unit in the continuous processing process.