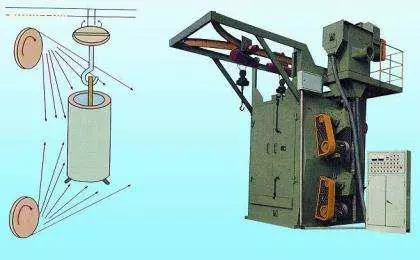

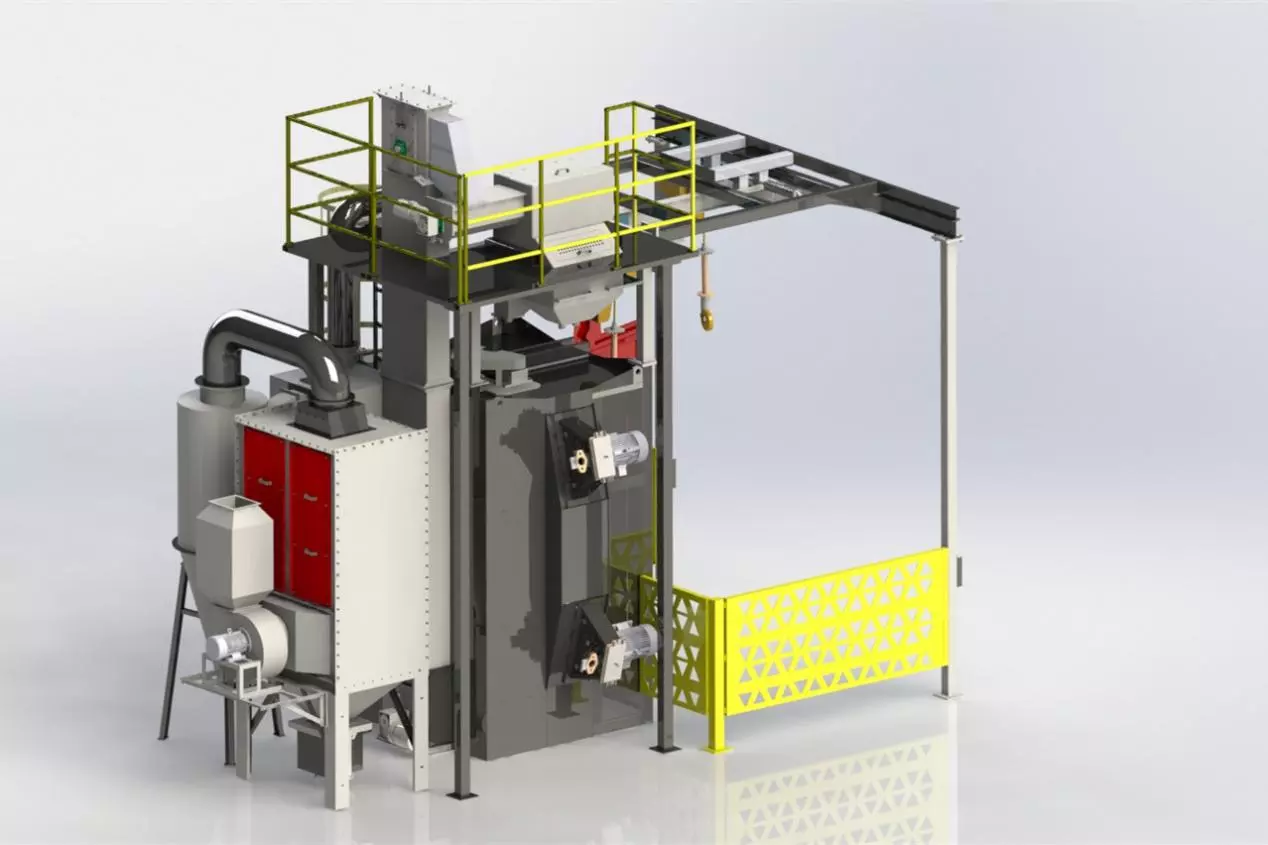

Influencing factors of abrasives mechanical strength, and impellers

What is the specific definition of strength and shot peening in shot blasting machinery? Strength: In mechanics, the ability of a material to resist damage under external forces, like resistance to deformation or fracture, is called strength. Moreover, this performance is one of the basic requirements that mechanical components must meet and satisfy. Shot peening: shot peening is a surface strengthening process widely used in shot blasting machines. It has the advantages of simple equipment, convenient...