Metal Abrasives

Steel Shot

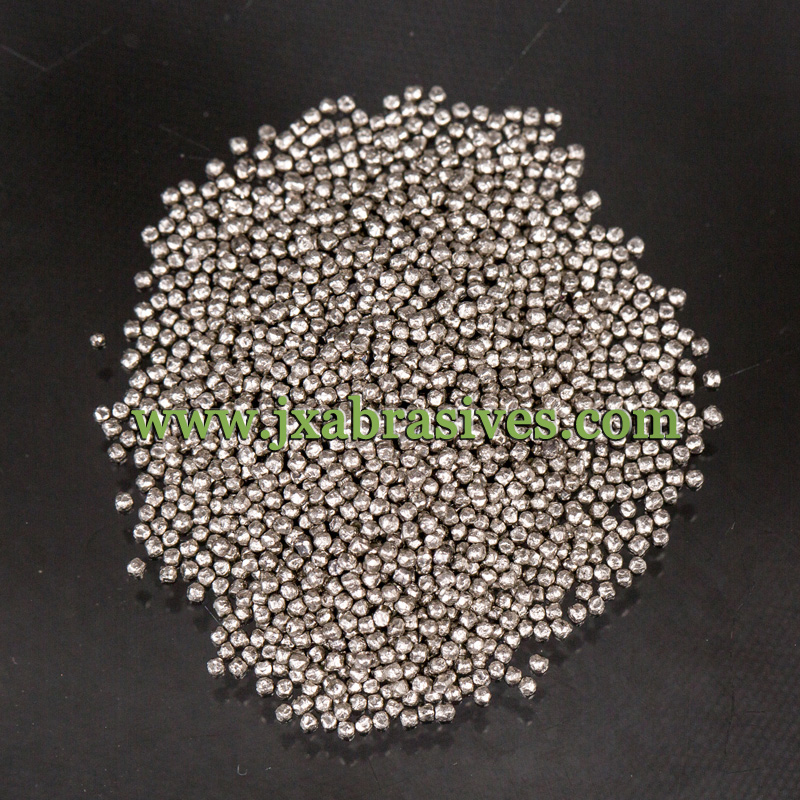

JX Steel Shot is a kind of round particles which made from top quality material by special heat treatment. It is widely used in surface cleaning and shot peening for the majority of wheel blast applications. With the best elasticity and fatigue resistance, JX steel shot is the most durable and maximum cleaning effiency.

Application:

Blast cleaning: use for blast cleaning of steel board, H type steel, steel pipe and all kinds of steel material, casting, die-casting, gorging, glass surface for industries of steel structure, construction, bridge, shipbuilding, pipes, container, locomotive, engineering machinery, automobile, casting , forging, glass, commodity.

Shot peening: used for shot peening of spring, shaft, gear, connecting bar, blade, chain, crank, wheel spares for industries of automobile, locomotive, ship, plain, machine.

Application:

Blast cleaning: use for blast cleaning of steel board, H type steel, steel pipe and all kinds of steel material, casting, die-casting, gorging, glass surface for industries of steel structure, construction, bridge, shipbuilding, pipes, container, locomotive, engineering machinery, automobile, casting , forging, glass, commodity.

Shot peening: used for shot peening of spring, shaft, gear, connecting bar, blade, chain, crank, wheel spares for industries of automobile, locomotive, ship, plain, machine.

| SAE | Application | Size(mm) |

| S-70 S-110 S-170 |

Stainless steel plate, sheet steel, non-ferrous alloy surface prior to coating process, enhance flexibility and toughness, wire strengthening treatment |

0.18 - 0.355 0.3 - 0.5 0.42 - 0.71 |

| S230 S280 |

Small cast, small casting products, heat treatment products, cast aluminum, steel plate, cast copper alloy, gold-plated prior to treatment, and enhance the flexibility and toughness |

0.6 - 0.85 0.71 - 1.0 |

| S-330 S-390 |

Medium & small cast iron, malleable iron, small pieces of casting & heat treatment products, steel plate, structure steel, steel pipe, chain, non-ferrous alloy (derusting, strengthen, forming) |

0.85 - 1.2 1.0 - 1.4 |

| S-460 S-550 |

Large and medium-sized cast iron, cast steel, forgings, heat-treated pieces, steel plate steel pipes (derusting, strengthen, forming) |

1.2 - 1.7 1.4 - 2.0 |

| S-660 S-780 |

Large cast iron, cast steel, cast iron pipe, large forgings, heat-treated pieces (derusting) | 1.7 - 2.3 2.0 - 2.8 |

JX 15 SS 01

Buy Steel Shot from JX Abrasives Manufacturer in China, durable cast steel shot, >7.3g/cm, widely used in surface cleaning and shot peening.

Steel Grit

JX Steel Grit has sharp edges that help cleaning the surfaces easily. They are used for different applications: ship building, pipe building, steel construction, granite cutting, tank manufacturing etc.

Application:

Blast cleaning: use for blast cleaning of steel board, H type steel, steel pipe and all kinds of steel material, casting, die-casting, gorging, glass surface for industries of steel structure, construction, bridge, shipbuilding, pipes, container, locomotive, engineering machinery, automobile, casting, forging, glass, commodity.

Application:

Blast cleaning: use for blast cleaning of steel board, H type steel, steel pipe and all kinds of steel material, casting, die-casting, gorging, glass surface for industries of steel structure, construction, bridge, shipbuilding, pipes, container, locomotive, engineering machinery, automobile, casting, forging, glass, commodity.

| SAE | Application |

|

G-12 G-14

G-16

|

Cleaning up large and medium sized casting steel, cast iron, forged products, rolled steel, steel plate, rubber adhesive before processing. |

| G-18 G-25 G-40 |

C stone cutting, grinding, rubber adhesive pre-processing, steel plate, container, steel hull coating pre-treatment, spray medium and small steel, cast iron, forged products, etc. |

| G-50 G-80 G-120 |

Steel wire, wrenches, pipe, the pre-plating treatment, precision casting products (such as golf head) of the spray. |

JX 15 SG 03

Buy Angular Bearing Steel Grit from JX Abrasives Manufacturer, angular steel grit, Hardness≥HRC62, more Cr contain, high efficiency for blasting.

JX 15 SG 02

Purchase Rail Steel Grit from JX Abrasives Manufacturer in China, rail steel grit, high Mn contain (0.7-1.5%), angular sharp, high wear resistance.

JX 15 SG 01

Buy GP GL GH steel grit from JX Abrasives Manufacturer in China, SAE J444 steel grit, Size G10, G12, G14, G16, G18, G25, G40, G50, G80, G120.

Cut Wire Shot

Cut Wire Shot is produced by cutting high quality wire into the form of cylinders with lengths approximately equal to the wire diameter. It’s available in cylinder and conditioned (spherical) shape.

| Wire Material | Carbon Steel, Stainless Steel, Aluminium, Zinc, Copper and Nickel Alloys |

| Standard | SAE J441, AMS 2431, DIN 8201, VDFI 8001, ISO 11124 , MIL-S-13165 |

| Application | Shot peening, blasting, tumbling & vibratory finishing |

| Industry - automotive, aerospace, foundry & forge, energy, shipyard, railway, etc. | |

| Advantages | High durability can reduce the production cost and time |

| Stable working effect due to high consistency in size, density, and hardness | |

| No breakdown and less dust are better to the environment | |

| Reduce the maintenance cost for machines | |

| Fatigue life of work pieces would be increased by using conditioned shot | |

| Varieties of wire material and hardness can be selected to match the work piece |

JX 15 CWS 04

Buy aluminum shot from JX Abrasives Manufacturer in China, aluminum cut wire shot to clean, reinforce aluminium, zinc, nonferrous casting parts.

JX 15 CWS 03

Buy copper shot from JX Abrasives Manufacturer in China, 0.6-3.0 mm copper cut wire shot, 100-200 HV, for polishing, peening of hardware parts.

JX 15 SS 01

Buy Stainless Steel Shot from Jinxing Abrasives Manufacturer in China, Stainless Steel Shot 0.2-3.0 mm, 7.7g/cm3, SUS 304, SUS 202, SUS 430 grades.

JX 15 CWS 01

Buy zinc shot from JX Abrasives Manufacturer in China, 0.6-3.0 mm zinc cut wire shot, 35-55HV, 7.1g/cm3, for deflashing & finishing die castings.