H Beam Shot Blasting Machines for Surface Cleaning

Key Specifications / Features

Model No.: JX- RCBM-13

Hits: 314

H Beam Shot Blasting Machine Factory JX Provides H Beam Shot Blasting Machines for Surface Cleaning and Strengthening, to Improve the Quality of Surface.

Request a quote

Tags

Detail Information

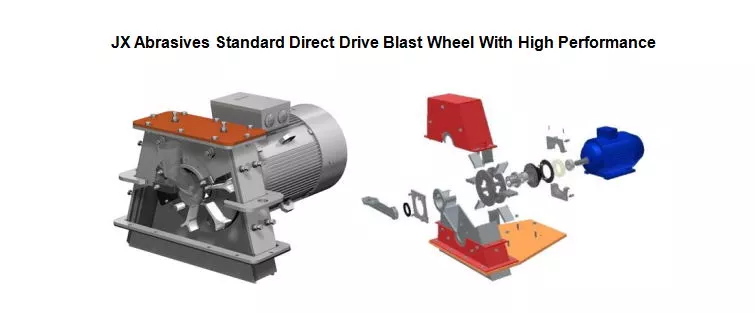

JX H beam shot blasting machine are automatically table roller continually passing type. This type of machine is especially used for steel H beam surface cleaning and strengthening, to get a certain degree of surface roughness, to add paint adhesion force, to improve surface quality and to enhance anti-corrosive effects. There is a shot blaster on each side of the shot blasting room. They are assembled in the best position according to the H beam condition.

Technical Parameters:

1. Blasting chamber

Blast Chamber Open Size: 2500mm—1200mm

2. Blasting nozzles

1) Model: Q034H

2) Shot blasting volume : kg/min 250—10

3) Power: kw 15—10

4) Quantity: Set 10

Blast Chamber Open Size: 2500mm—1200mm

2. Blasting nozzles

1) Model: Q034H

2) Shot blasting volume : kg/min 250—10

3) Power: kw 15—10

4) Quantity: Set 10

If you' re interested in our style machine, welcome to contact us to get more detailed info.

This machine is not a standard machine, any parameters can be customized according to clients' requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions.

This machine is not a standard machine, any parameters can be customized according to clients' requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions.

Machine Details:

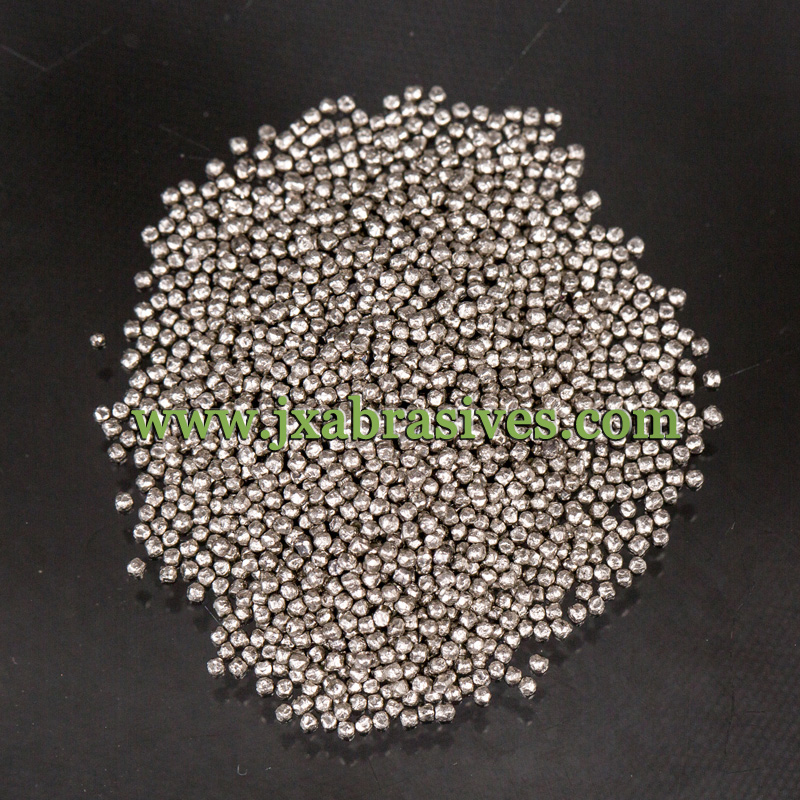

The steel shots blasted by blasting turbines will be collected and purified by the shots circle system, and then continue to be used again by blasting turbines.

The process flow of the shots circle system: Steel shots blasted by blasting turbines will be collected by the portrait screw conveyor and delivered to the bucket elevator. Finally, the bucket elevator will lift them to the air wash type separator.

After separating, the dust and broken steel shots will be removed from steel shots and good steel shots will enter the storage bin.

FAQ:

1. The max. Length/Width/Height of the work pieces.

2. The productivity you need to blast the work pieces (how many tons or pieces per day or per month?).

3. The power supply you need (such as 380V, 3P, 50HZ).

4. The work pieces photo or drawing is better.

Based on these questions, detailed technical proposals will be sent to you for reference.

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer's shot-blasting needs. If you have special requirements, please download Blasting Equipment Questionnaire for your reference.

Comment Form