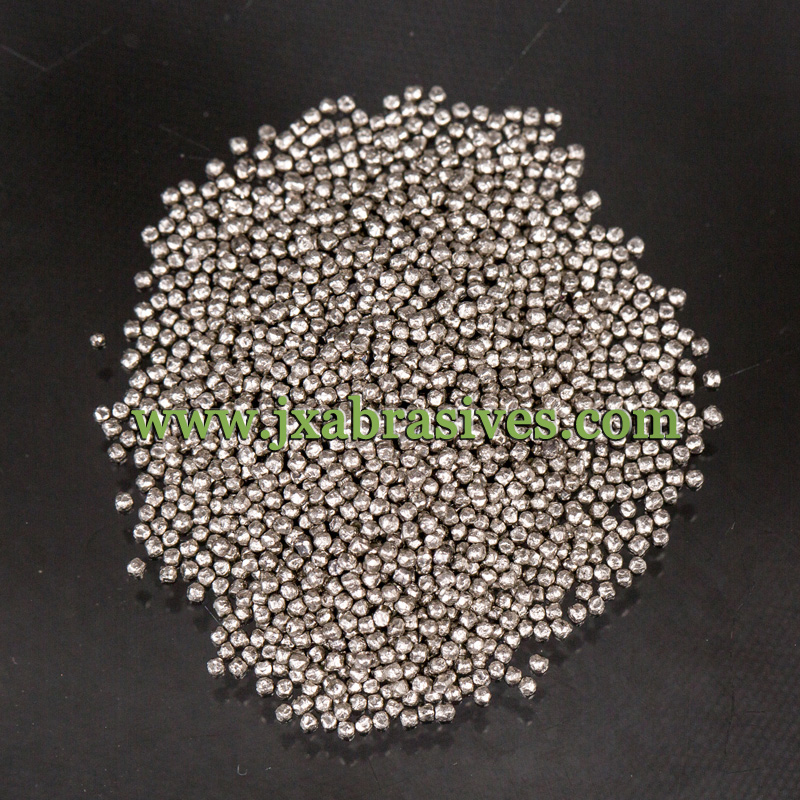

Cut Wire Shot

Cut Wire Shot is produced by cutting high quality wire into the form of cylinders with lengths approximately equal to the wire diameter. It’s available in cylinder and conditioned (spherical) shape.

| Wire Material | Carbon Steel, Stainless Steel, Aluminium, Zinc, Copper and Nickel Alloys |

| Standard | SAE J441, AMS 2431, DIN 8201, VDFI 8001, ISO 11124 , MIL-S-13165 |

| Application | Shot peening, blasting, tumbling & vibratory finishing |

| Industry - automotive, aerospace, foundry & forge, energy, shipyard, railway, etc. | |

| Advantages | High durability can reduce the production cost and time |

| Stable working effect due to high consistency in size, density, and hardness | |

| No breakdown and less dust are better to the environment | |

| Reduce the maintenance cost for machines | |

| Fatigue life of work pieces would be increased by using conditioned shot | |

| Varieties of wire material and hardness can be selected to match the work piece |

JX 15 CWS 04

Buy aluminum shot from JX Abrasives Manufacturer in China, aluminum cut wire shot to clean, reinforce aluminium, zinc, nonferrous casting parts.

JX 15 CWS 03

Buy copper shot from JX Abrasives Manufacturer in China, 0.6-3.0 mm copper cut wire shot, 100-200 HV, for polishing, peening of hardware parts.

JX 15 SS 01

Buy Stainless Steel Shot from Jinxing Abrasives Manufacturer in China, Stainless Steel Shot 0.2-3.0 mm, 7.7g/cm3, SUS 304, SUS 202, SUS 430 grades.

JX 15 CWS 01

Buy zinc shot from JX Abrasives Manufacturer in China, 0.6-3.0 mm zinc cut wire shot, 35-55HV, 7.1g/cm3, for deflashing & finishing die castings.