Automatic Aluminum Profile Shot Blasting Machine

Key Specifications / Features

Model No.: JX- RCBM-10

Hits: 290

Aluminum Profile Blasting Machine Manufacturer JX Abrasives Provides Offers Automatic Aluminum Profile Shot Blasting Machine with 4 Blasting Wheels.

Request a quote

Tags

Detail Information

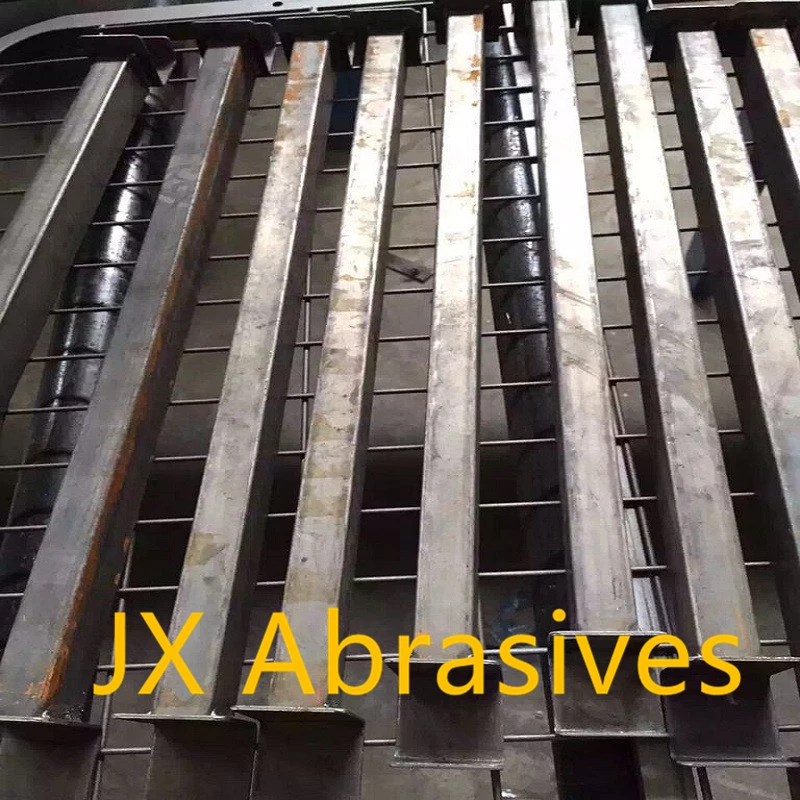

Automatic aluminum profiles shot blasting machine

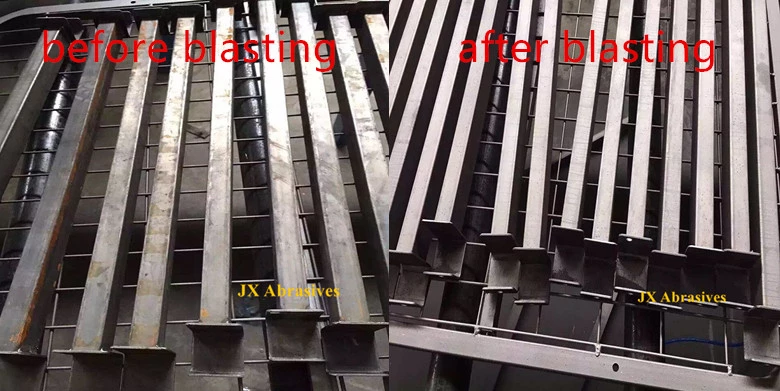

It is used for surface treatment of profiles in aluminum. The profiles in aluminum are manually or automatically contained on the roller conveyor by loading devices. There are four blasting wheels blasing the workpiece which passes through the blasting room.

Typical Application:

Rust and heat scale removal

Paint stripping

Surface texturing

Preparation for painting, bonding and plating

Deburring, deflashing

Cleaning

Technology Parameter(Customized is available):

This machine is not a standard machine, any parameters can be customized according clients' requirements, so any further information please contact with us, our skilled engineer team will give you the most professional and cost-effective solutions.

Machine Details:

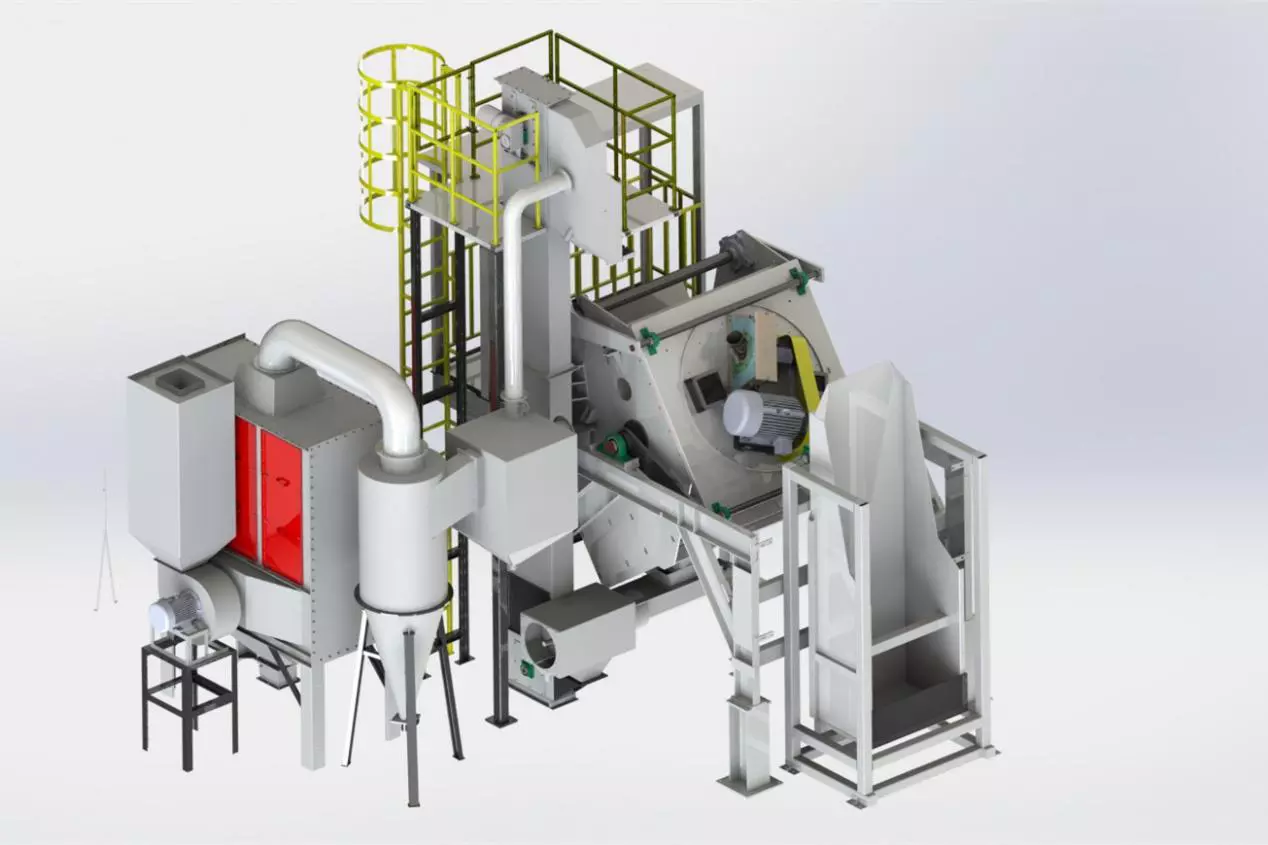

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit

4. Bucket Elevator unit

5. Abrasive Separation/Cleaning system with Storage Hopper

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with PLC Control System.

-755x313.webp)

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer's shot-blasting needs. If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

It is used for surface treatment of profiles in aluminum. The profiles in aluminum are manually or automatically contained on the roller conveyor by loading devices. There are four blasting wheels blasing the workpiece which passes through the blasting room.

Typical Application:

Rust and heat scale removal

Paint stripping

Surface texturing

Preparation for painting, bonding and plating

Deburring, deflashing

Cleaning

Technology Parameter(Customized is available):

| Parameter | DX-Q08 | DX-Q12 | DX-Q15 | DX-Q20 | DX-Q25 | DX-Q30 | DX-Q40 |

| The effective ckeaningwidt(mm) | 800 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Dimension of inlet opening(mm) | 1600*800 | 1200*400 | 1700*400 | 2200*400 | 2700*800 | 3200*800 | 4200*400 |

| The length of cleaning workpiece(mm) | 1200-12000 | 1200-1600 | 1200-12000 | 1200-12000 | 3000-12000 | 2400-12000 | 4500-18000 |

| The speed of conveyor(m/min) | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| The thickness of cleaning steel sheet | 3-60 | 3-60 | 1.5-60 | 3-60 | 3-60 | 3-110 | 4.5-100 |

| Abrasives flow rate | 4*120 | 4*250 | 4*250 | 6*250 | 6*250 | 6*360 | 6*360 |

Machine Details:

These Type of Machines consist of under mentioned Parts:

1. Main Blast Cabinet with inspection Door

2. Blast Wheel Units with Drive Mechanism.

3. Abrasive circulation unit

4. Bucket Elevator unit

5. Abrasive Separation/Cleaning system with Storage Hopper

6. Dust Collector with Cleaning Mechanism.

7. Roller Conveyor system at Inlet & Outlet Side.

8. Control Panel with PLC Control System.

-755x313.webp)

JX Shot Blasting Machine offers upgraded transport technology, high-efficient blast wheels and multiple machine sizes and types adhere to the customer's shot-blasting needs. If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Comment Form